- Johnson Controls

- Oil and Gas

- Fire Suppression

- Grooved Couplings and Fittings

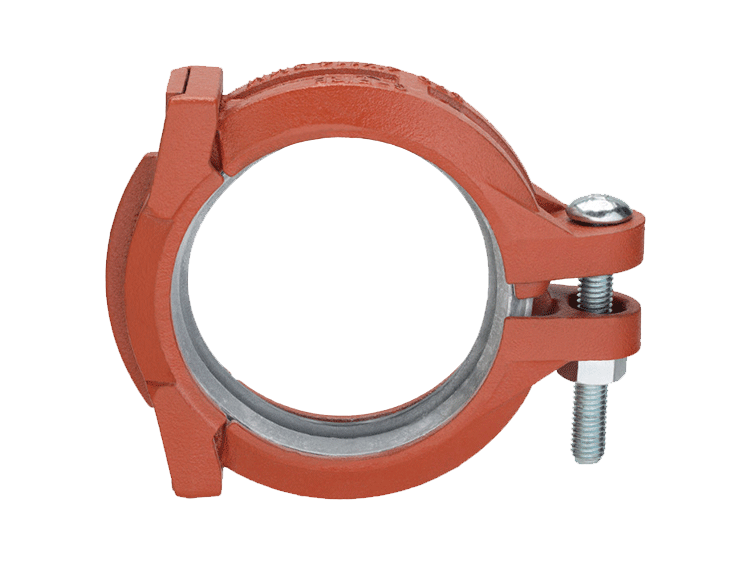

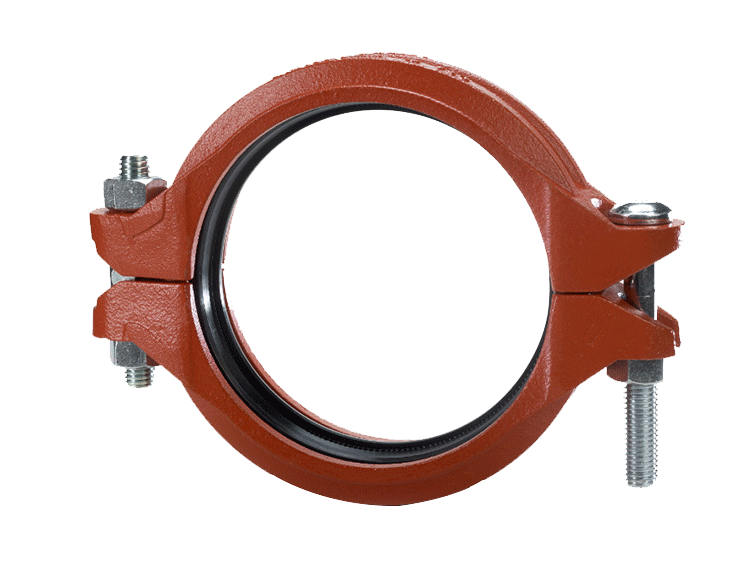

Grooved Couplings and Fittings

Why Grooved?

We deliver quality grooved piping solutions for a full range of fire applications, which install faster and are more cost-effective for joining pipe than traditional welding methods. Grooved couplings and fittings allow installers to fabricate on-site and around complex obstacles. No special tools are needed, fire permits are not required, nor do building residents have to evacuate due to welding fumes. And grooved products eliminate the need for expansion joints, maintaining high pressure at each connection without sacrificing quality and reliability.

Fast Assembly

Grooved systems allow for quick, simple, and consistent installation.

Cost-effective

Reduce labor costs and the need for fire or hot-works permits.

Compatibility With Hazardous Environments

No welding or cutting means grooved products are ideal for hazardous sites.

Stay one step ahead with news and insights from our fire systems experts.

See All Insights

Blog

Fire Suppression

Common Causes of Electrical Fires

.png?la=en&h=70&w=157&hash=717A494A27ED61C45CEF95AC3A9C6309)